Wind Tunnel Project

Featured Project

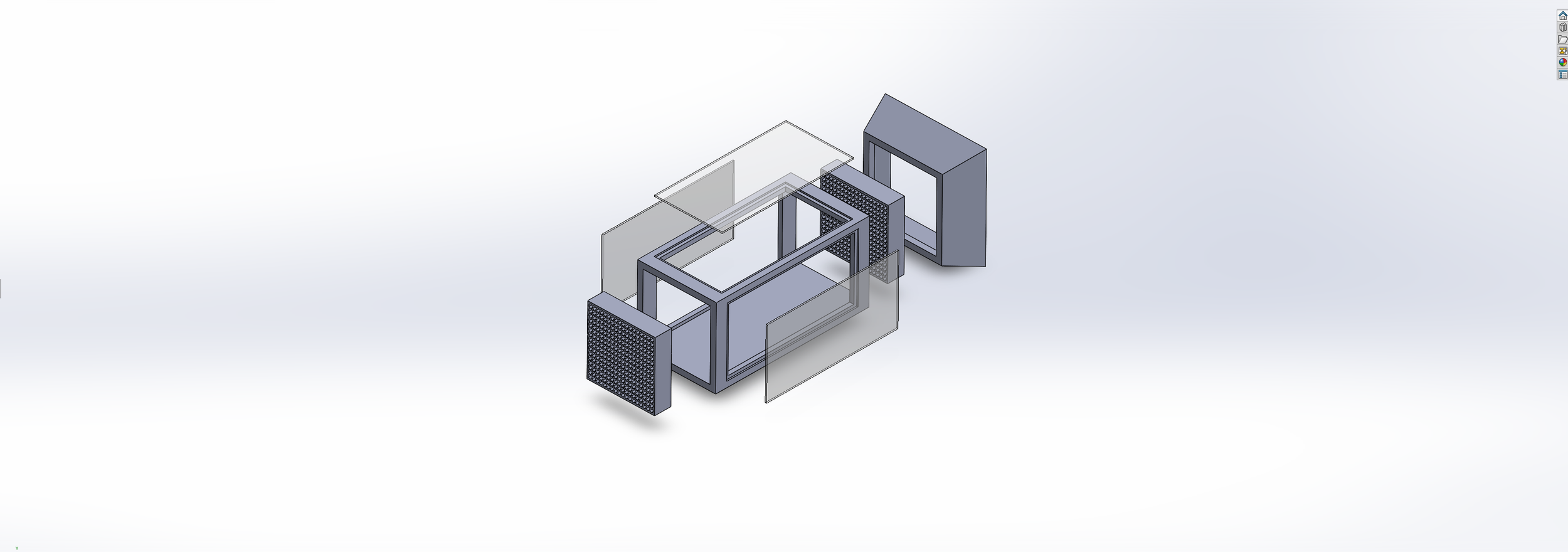

Precision-Engineered Wind Tunnel Prototype

Designed and modeled a fully functional subscale wind tunnel using SolidWorks, complete with a hexagonal honeycomb flow straightener, modular acrylic side panels, and an integrated exhaust outlet. Optimized for 3D printing using PLA with precision fit and structural rigidity in mind.

This project highlights my CAD proficiency, rapid prototyping workflow, and engineering design skills in fluid dynamics applications.

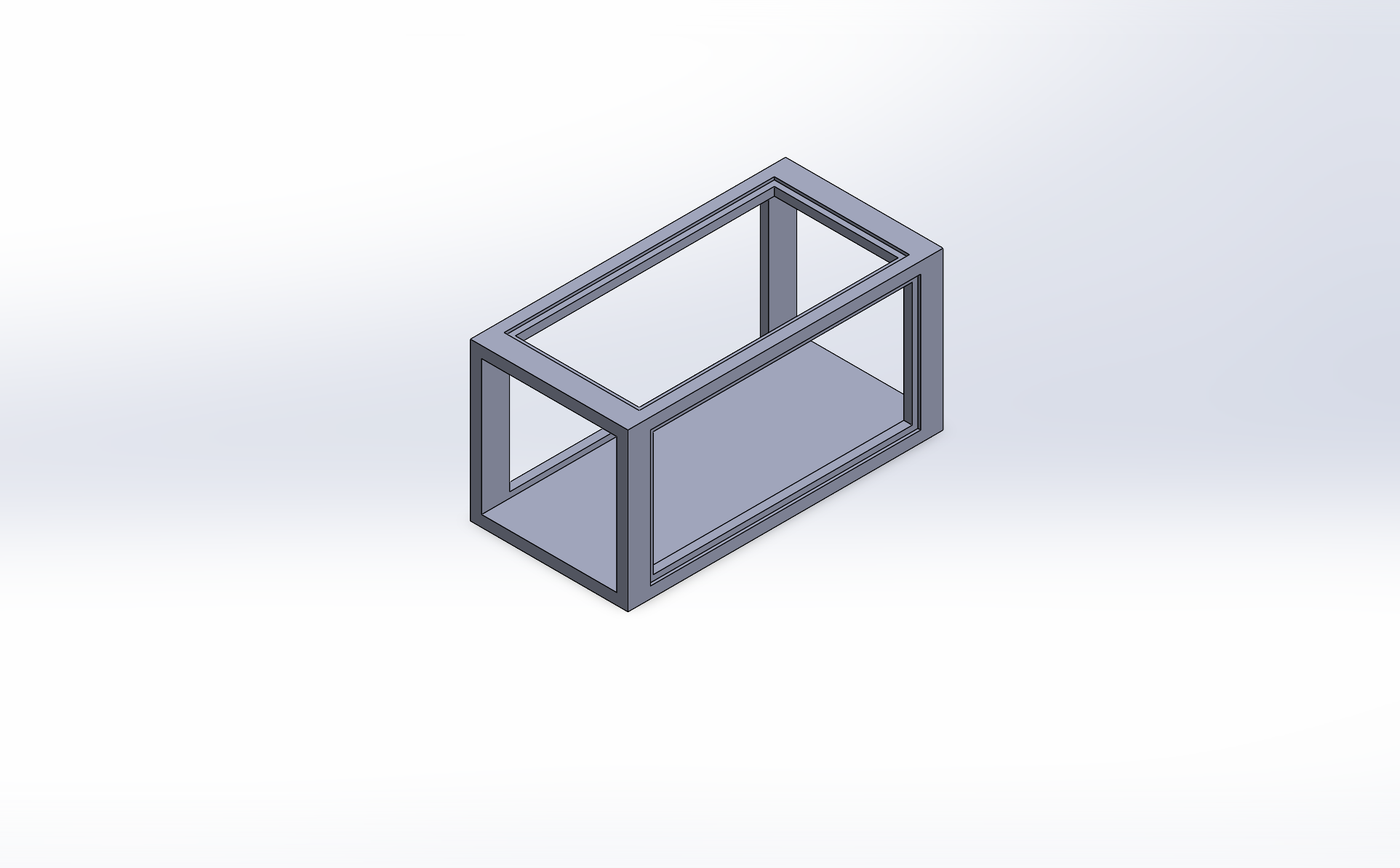

The Tunnel

This is the base design for a wind tunnel I'm working on. It's not fully built or functional yet — just the structural layout for now. The goal is to eventually use it to study how air flows around different shapes and models. It's a first step toward learning more about aerodynamics and building something real from scratch.

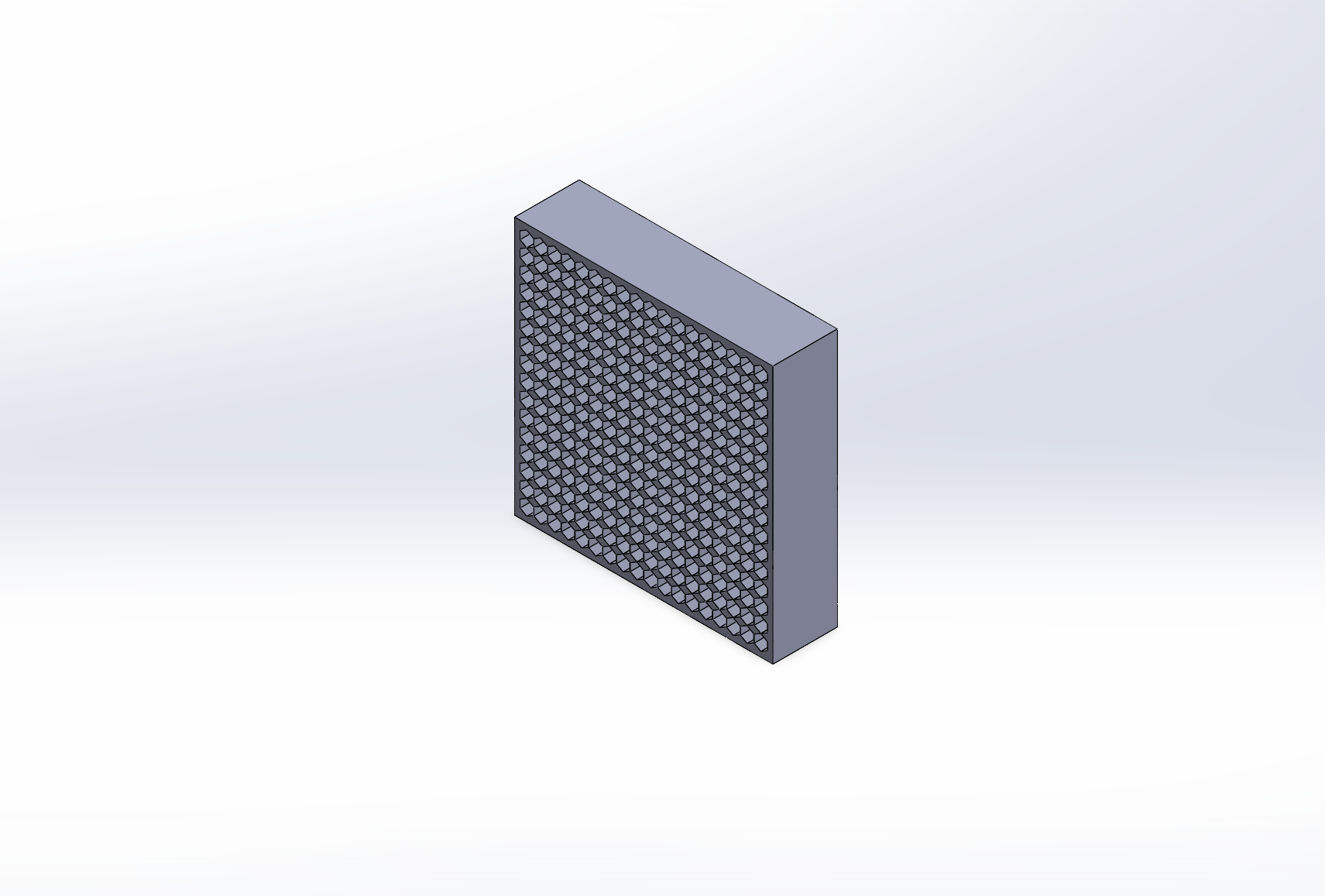

The Honey Comb

This honeycomb flow straightener plays a crucial role in preparing the airflow before it enters the main test section of the tunnel. Its purpose is to take chaotic, turbulent air and channel it into clean, uniform, laminar flow — a key requirement for accurate aerodynamic testing.

The hexagonal cells help eliminate swirls and vortices by forcing the air to travel in straight, parallel paths. This improves consistency and reliability when testing objects downstream. I modeled this part with inspiration from real-world wind tunnels used in aerospace and motorsport engineering.

While it may seem simple at first glance, this component is essential for reducing noise in data and improving test quality. Designing it taught me a lot about the practical side of fluid dynamics — and it's one of the features I'm most proud of.

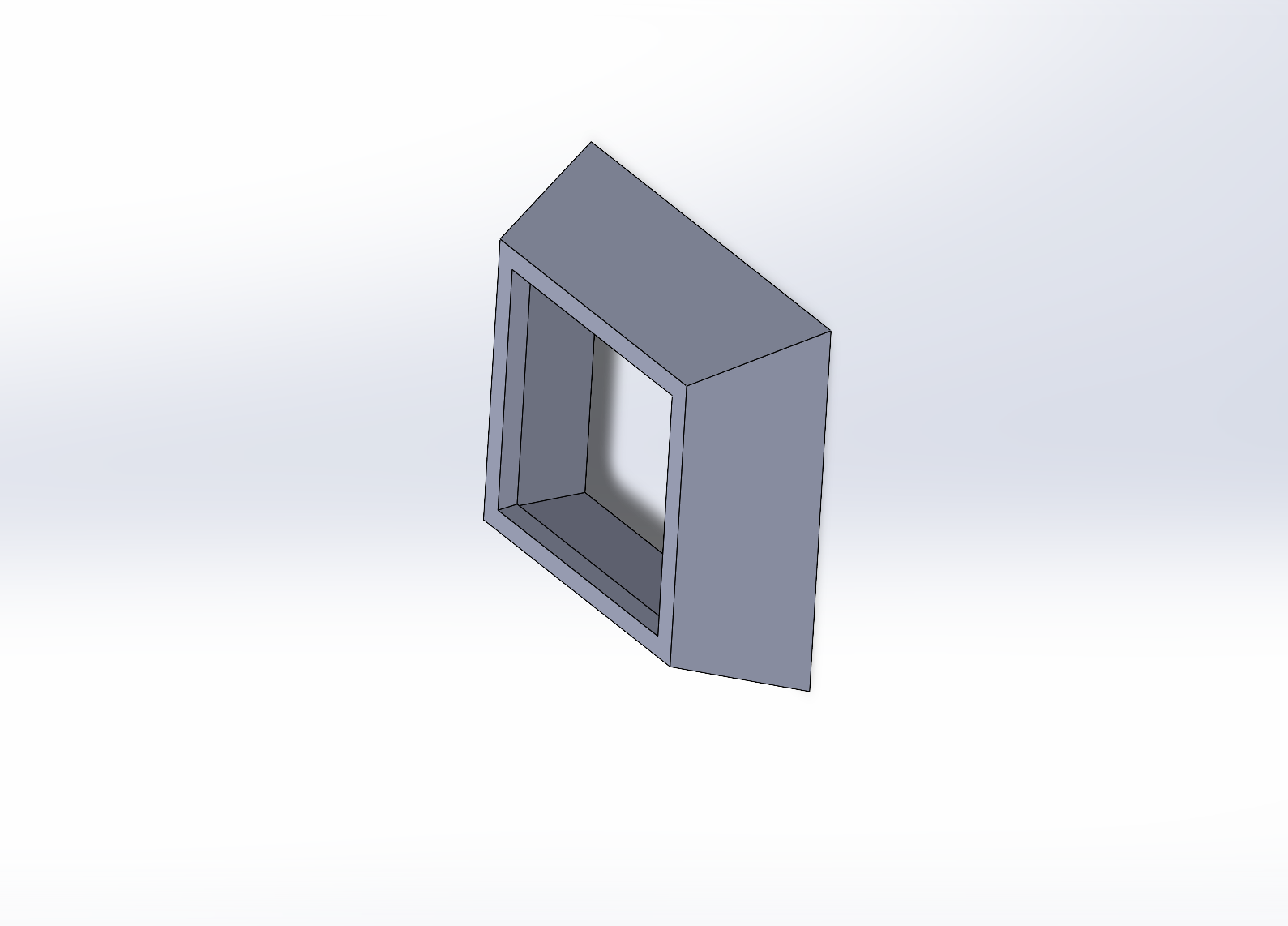

Exhaust Outlet

This is the final section of the tunnel where the air exits after flowing through the test section. It's shaped to help reduce back pressure and guide airflow smoothly out of the system. A fan will be attached at the end to pull air through the tunnel, which helps maintain a steady, consistent flow. Simple but important for keeping things efficient and clean.