Jet Turbine Project

Featured Project

CF6-80C2 Turbofan Jet Engine

Modeled after the General Electric CF6-80C2, this 3D CAD project demonstrates the full architecture of a high-bypass turbofan jet engine. I focused on cutaway visualization, component clarity, and mechanical accuracy to reflect real-world gas turbine design.

This project highlights my proficiency in CAD assembly, sectional views, and turbine propulsion system understanding — essential skills for future work in aerospace propulsion and thermodynamics.

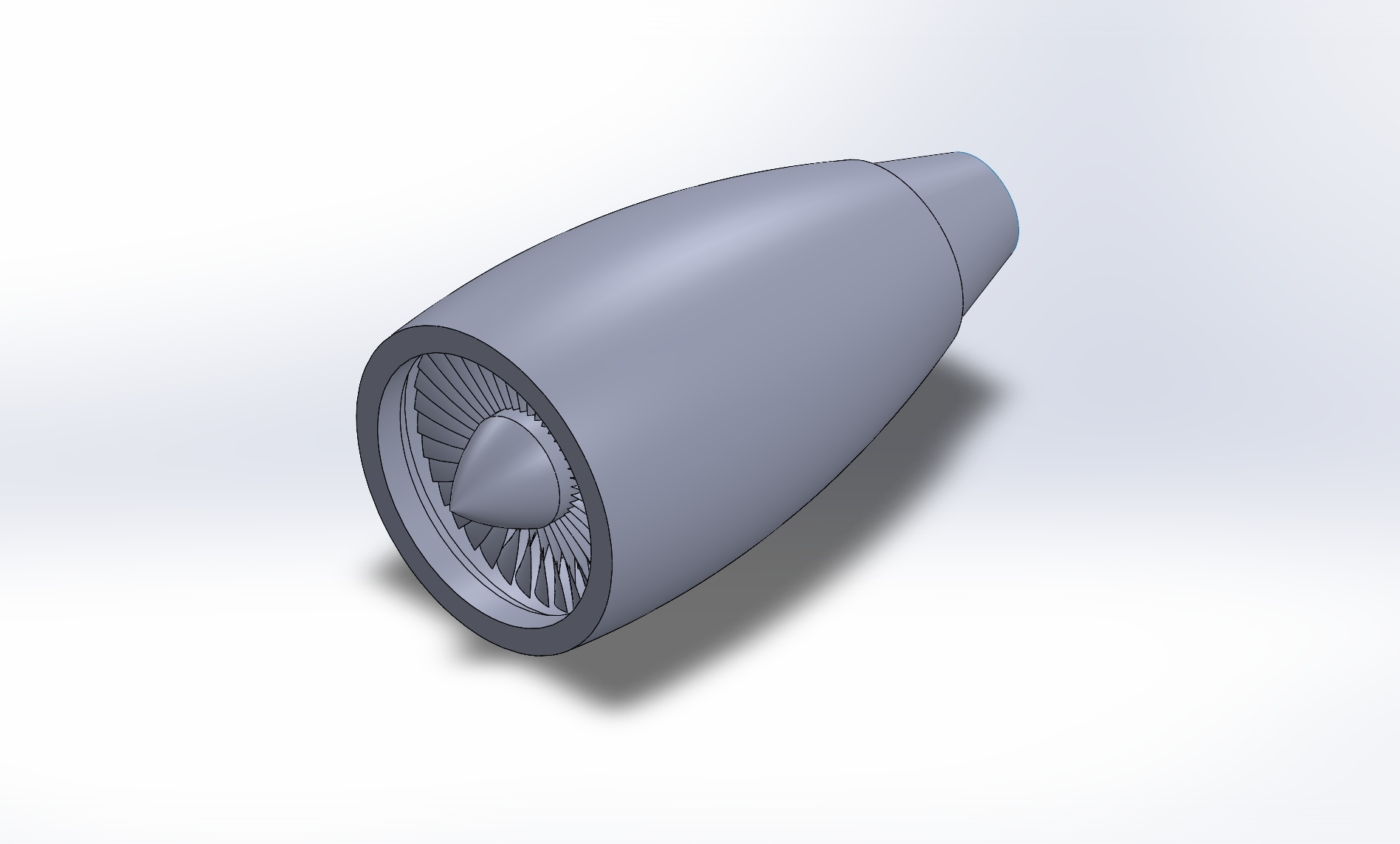

Full Exterior View

Rendered side view of the CF6‑80C2 turbofan showing the nacelle, fan casing, and spinner. This high-bypass engine is known for its role in powering aircraft like the Boeing 747 and military C-5M Super Galaxy.

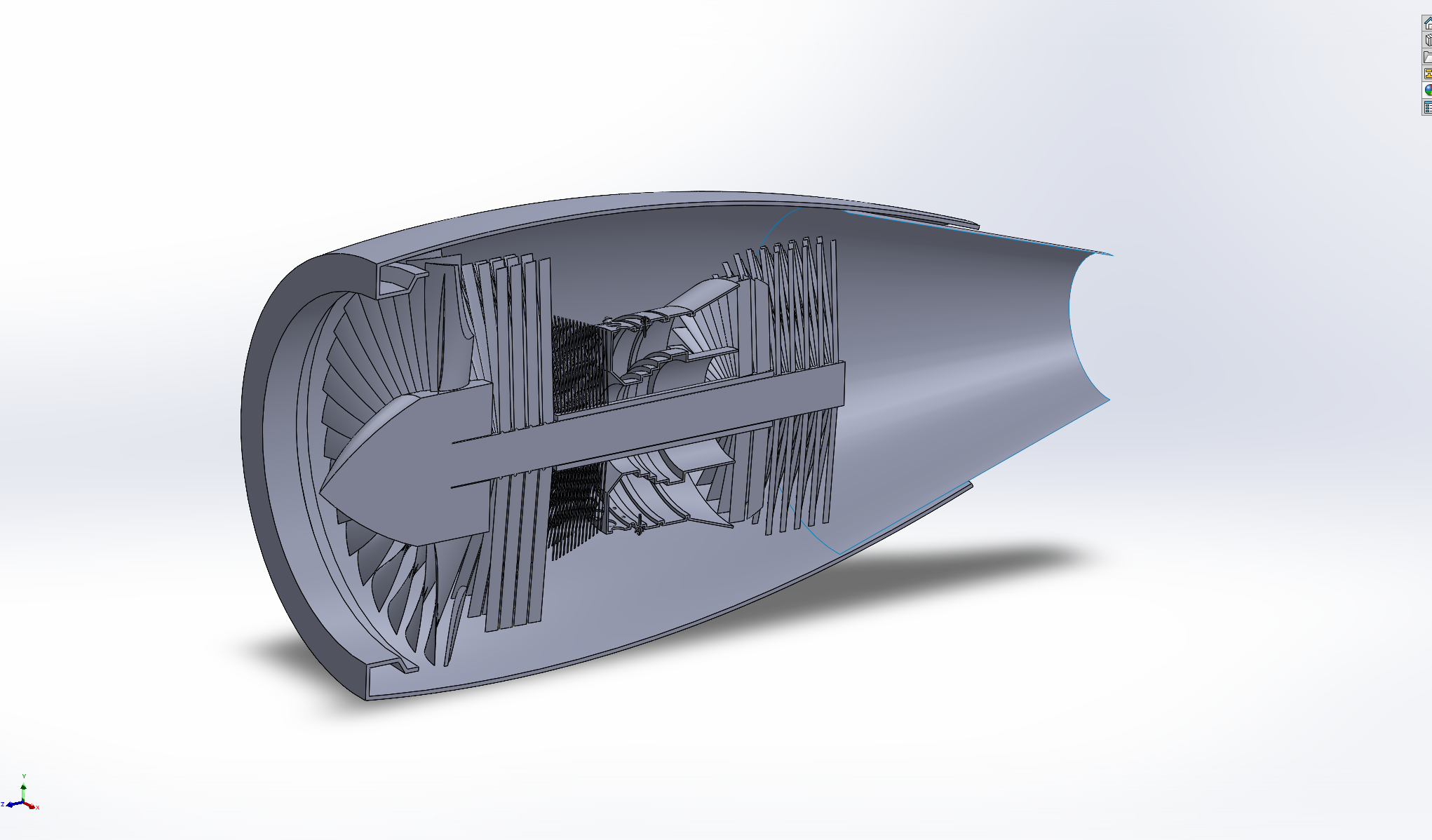

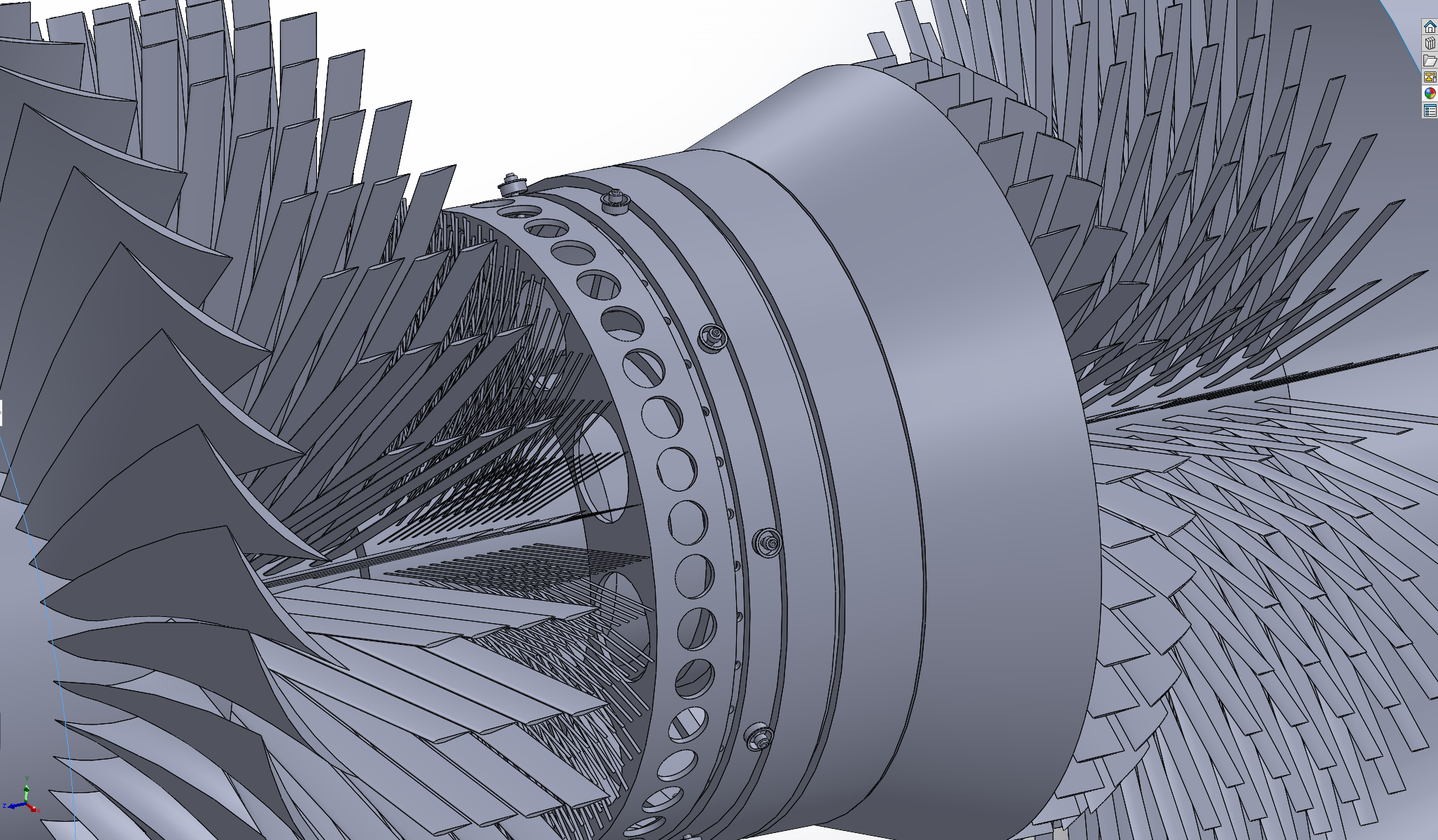

Cross-Sectional Architecture

Detailed longitudinal cutaway showing internal components: fan, LPC, HPC, combustor, HPT, LPT, and exhaust. You can see the N1 and N2 shaft system architecture with multiple turbine/compressor stages driving airflow compression and power extraction.

Combustion Chamber

The combustion chamber mixes high-pressure air from the HPC with atomized fuel injected through precision nozzles. Once ignited, the high-temperature exhaust drives both turbine stages to extract usable mechanical energy.

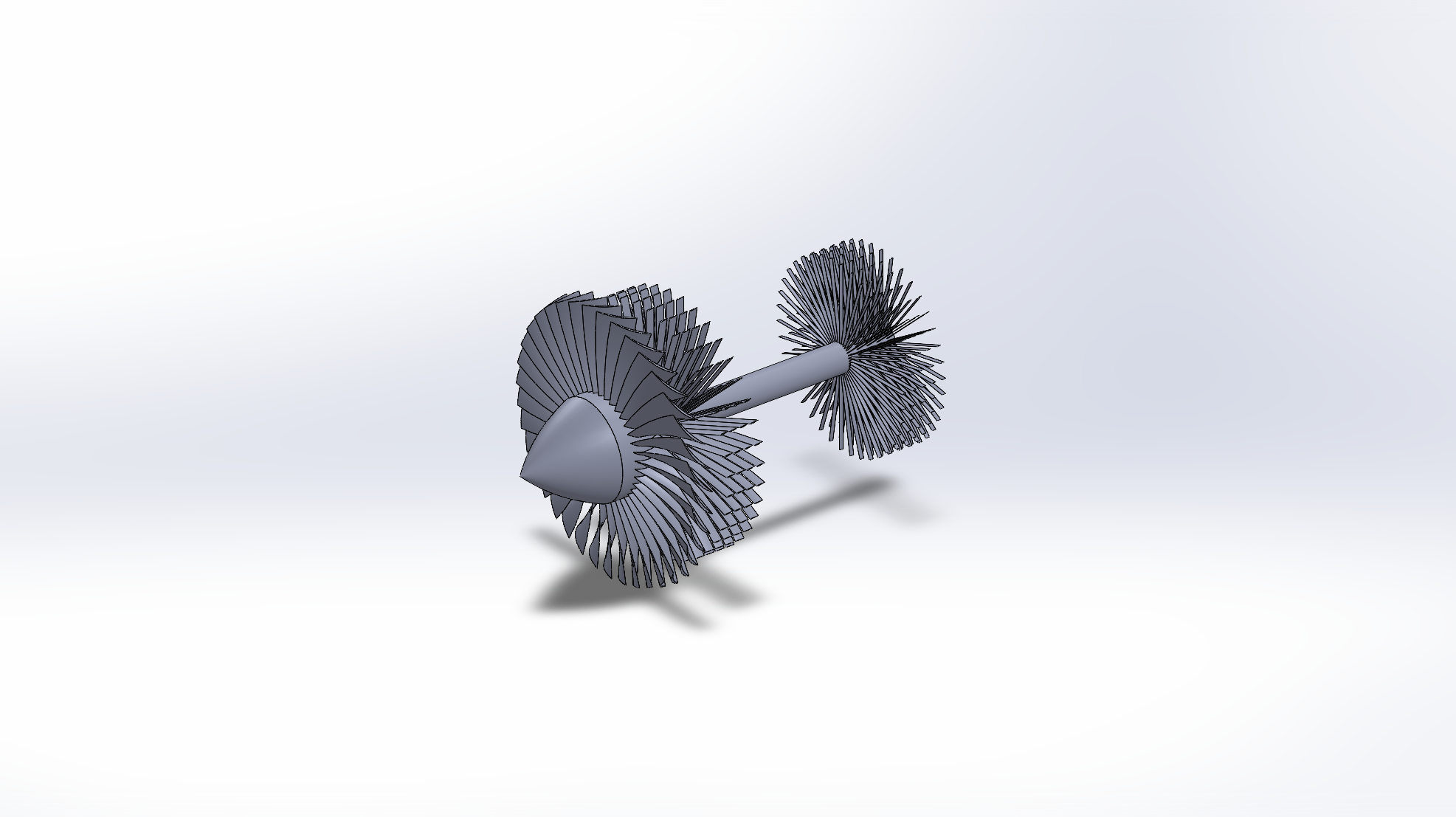

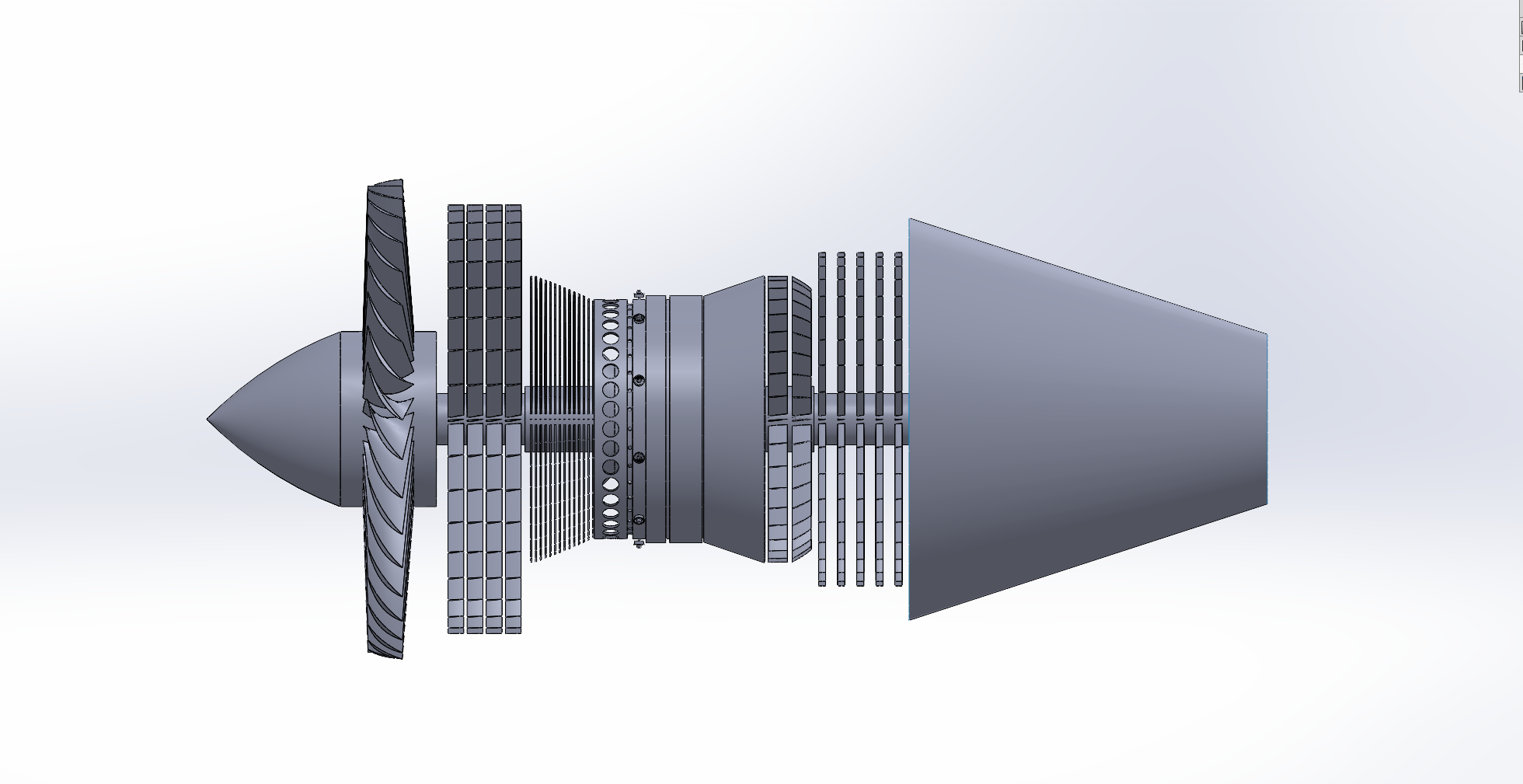

LPC and LPT Stages

This view focuses on the Low-Pressure Compressor and Low-Pressure Turbine. The LPT extracts energy from the hot gases to drive the massive front fan via the N1 shaft — essential to the thrust output in a high-bypass turbofan.